Button Holes and Decorative Stitching

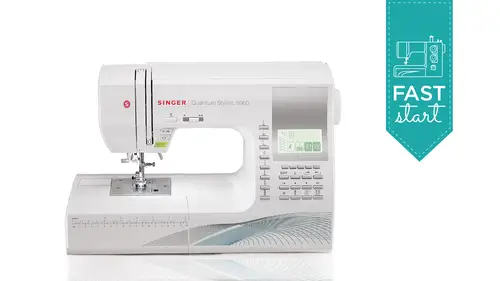

Lesson 4 from: Singer Quantum Stylist™ Sewing Machine Model 9960 - Fast StartBecky Hanson

Button Holes and Decorative Stitching

Lesson 4 from: Singer Quantum Stylist™ Sewing Machine Model 9960 - Fast StartBecky Hanson

Lessons

Machine Overview

13:06 2Bobbin Types and Thread Tension

23:11 3Basic Needle Styles and Threads

16:50 4Button Holes and Decorative Stitching

29:22 5Twin Needle and Blind Hem

21:48 6Ribbing Insertion and Free Motion

28:38 7Thread Painting and Flower Stitcher

15:11 8Additional Foot Attachments

15:34Lesson Info

Button Holes and Decorative Stitching

Let's go ahead and try let's do a buttonhole so over here this is my buttonholed foot and to take the presser foot off the machine I'm gonna press this button and this foot is going to just drop right off and we're going to replace it with our buttonhole foot and to do that I'm going to set a button how it knows how how big of a buttonhole to make is it's going you're going to set your button in here and closed closed this on the button and there's a plate here that is it's called you're under plate you khun so with this or without it you don't have to use it but what it does is it will hold the fabric securely as its sewing um and so it's moving the foot moving the fabric and the foot together the foot isn't gliding over the fabric everything is working together so let us go ahead and if you if this is great for when you're sowing near the edges of something but let's say you wanted to put a buttonhole like right in the middle of something how what do you do with that edge piece there...

will you just simply take this off and there are these grips on the bottom side so you can really put a buttonhole anywhere you wanted to so you can use it both waves and all your presser feet have this pin thiss little pin right here the presser foot pin all of these what here's your over edge foot there's a pin that clips onto this little claw so to speak on the shank the way the school often on you just line that up over there and to split that snap on you don't need to put your foot underneath here and try to push it on I see that people do that a lot they're trying toe put this on and push it up but you don't need to do that they'll just kind of click in place like so and your buttonhole foot does the same thing it has its own little pin right there so you'll slide this on like so and just jiggle it around a little bit till you get the right spot and and then we're ready to put our fabric in here I got to draw my bob and thread because I had taken that out let me pull that up there we go I had taken that out to show you that so what's pullout up great no um I'll get some fabric for doing that here we go and place your fabric in between the plates when you're using the under plate the one thing you want to watch her run just get rid of this threat it's getting really long getting in my way okay um you need to pull your buttonhole ever down and it has to go in between this skied here and this guide here if you pull this down and it's behind your foot, this isn't going to feed. You need to pull this so it's down in between these two pieces right here and the other thing you want to watch for is you want to make sure your fabric goes in between the plates? I've seen folks the first time that they do this, they put everything underneath the plate and the foot like this, and you won't even so it'll so in one place and not even move, so you want to make sure that this is in between? The fabric is in between the two plates, so it'll kind of grip it like almost like a little embroidery hoop or something. Ok, and so we'll bring the presser foot lift her down and then you actually have on your machine. If you look on this top panel, there is a big selection of buttonhole styles to choose from. There is the small and large bar attack, which are kind of the standard buttonholes you've got keyhole buttonhole styles, keyhole with a appointed and you've got two different styles a round end you've got heirloom buttonholes, stretch buttonholes you have so many choices on a machine like this for all types of garments or home decor projects, he would make there's even an island stitch for making islands it's it's really great! And this is even these air darning stitches for darning using your buttonhole foot so you could actually darn over on air like a small hole you would open up your buttonhole foot for the length of however big that hole was and instead of putting a button in there, just open that slider up however big that was and then you would choose that stitch, which is number um sorry, I need my glasses one o three and you would go down here and she's stitch one o three and tell that stitching and darn but we're going to right now we're going to use just our basic quick touch buttonhole issues right here, which is our bartek button home no, I mean you can do is so one first to check to see if you like the priest at length and width of the stitch, and if you wanted to play with your tension than you, use your function button here, excuse me your you're you're stitch length to make it denser or more open, you can touch your length and with button on the function buttons here and this opens up a brand new screen for you. What I can see here is that I've got buttonhole s all the feet are labeled with a letter buttonhole foot f on the machine and it shows me a picture of the stitch I'm doing the number of it, and up here I would look in its one o for that's, the one I'm going to sew, and it says my with is default at five millimeters and my length is that o point five and if I want to change this, I can increase or decrease to my liking either my length or it's at maximum width right now, so I could bring that down if I wanted to. So you can you have complete control of this? I usually like to make one on a scrap first, make sure that it's looking the way I like making we might depend on the weight of the thread that I'm sewing with if I want to change that length, so we'll just go ahead and so one first and see what we've got. So press a foot lifter is down machine is threaded on and we'll go ahead and make one button home. Of course, you would probably have your thread match your fabric. I'm doing it in a high contrast so that you can see for what we're doing here today and it automatically stops and ties off. So I don't have to try to do a tie off or bring my threads to the back side and then cut them I can I can actually even no use my thread trimmer button to raise the needle it cuts the thread and I can just remove my work from the machine and here's my perfectly sewn it's just a loop that from that threat I turned earlier but there's my perfectly beautiful machine buttonhole. Now one of the things I showed the other groups that we've been doing the classes for this week is when you want to cut this open you can take a straight pin and put it in here near the end of your buttonhole and then use your seam ripper that's down here in your accessory trade turn this around and then you can just turn that little loop there that thread but put your seam ripper in here to carefully push that in and then cut your buttonhole open by having that pin up there on the end it's kind of like a little bumper so you don't cut too far and accidentally cut that bartek open because that would not be nice on your after you saw in your project to have cut your buttonhole open and that is how you make machine buttonholes and of course, if you wanted to, if you thought I want my stitches to be closer together a little more dense you would just come over on your screen and bring that stitch length down a little bit so another one it won't affect the length of the buttonhole at all because the mechanism is measuring the button itself it's simply um measures the button and so's more stitches in the sides of the button hole to give you a more dense look or you could leave it the way it is and changed to a little bit thicker thread it really just depends on how you want it to look so that's why I say try if you wanna scrap first to make sure you like the way it's looking ok so that was machine buttonhole so well I'm resetting this case we have any other questions can let's take a look? We do have some comments teresa saying I love how easy the button holes are they turn out beautifully and the pin idea is brilliant so thank you for that that za great help I mean you can just I feel like you in that last little bit you pushing and you go too far and then you've ruined it so that's that's great okay another or you get a button sewing foot so why don't we know that we've done a buttonhole? Why don't we still a button on and so here's a case where we're goingto take the extension trade off the machine and we're going to just drop those feed dogs and one thing I want to show you about this because we get calls on this a lot at the office is when I when I flip this switch to drop the feed dogs here's the feed dogs if you're if you're not familiar with some of this terminology the's little teeth that stick up here um as I turned the hand well you can see those moving they they come up, they take fabric that the presser foot comes down on the fabric which is pressing down on the feed dogs and the feed dogs come up meet the fabric, help push it along they drop down come around and with every stitch that happens very, very fast well when we're going to so free motion work or you're going to so in this case we're going to sew on a button I don't want them pulling my fabric cause I want to just zigzag in one place it's tio so my button on so we're going to drop the feed dogs and when you do that you'll actually physically see them drop out of the way like that so they're they're down below the level of the needle plate usually what happens where we get the calls on is when you put this back over to the other side to raise them for normal sewing again everyone expects them to pop back up just like they popped down, but what you have to do is turn your hand wheel one revolution for them to re engage so when you push that over to drop them down and you use it for either your button sewing or you're free motion work which will do in a little bit um when you go to reengage them again for normal sewing and you don't see them pop up no worries just turn your hand well, one full revolution and up they come so I just wanted to point that out to you if you've had that happen to you so we're going to drop them no. So for sewing on a button and this is our button sewing foot this was in your tray it looks a little bit like sort of like a little horseshoe, but sorry I hit the button there of my finger looks like a little soda horseshoe shape and when you place your your foot goes on just like all the other ones do they snap right on and we'll take that button that we used to so the buttonhole and will place that on our fabric underneath the button sewing foot and like so all right, so now you can either use a zigzag stitch or I believe you have a button sewing stitch, which is number thirteen so you would come here to your your utility stitch patterns and you press this button and now we're going to scroll to stitch number thirteen and there's a stitch it looks like a button on your screen but that's actually your button sewing stitch and it actually gave me a little indication in my window here to use that thing that looks almost like a little wrench that's ah diagram of your button sewing foot that has that little horseshoe shape on it it's it's a reminder that that's the foot you need to do that and you can go in and adjust your width of your stitch if you want to obviously we have no stitch length because there's no feeding here so length is irrelevant so that isn't even an option here on the screen you might want to change your stitch with because buttons don't all have the same distance in between the holes so before I really step on my foot controller I'm going to come over here in the front of my machine and I'm going toe I'm gonna um uh try my stitch and make sure that those that zigzag motion clears the holes if it seems like it's maybe touching the sides of your button a little bit you might wantto why not you're stitched just a hair cause your button might have the polls are bigger or their space further apart that looks like we're really nice and clear now get rid of this threat and then once we do that we can just step on the foot controller and let that so our button for us just back and forth and then we can come hair when we're finished to this top button on our direct select buttons when I press that it gives me a straight stitch in left position and I can just tap that a couple times to let it tack off and secure that button in place use my thread trimmer button to cut my threads and I removed my button and it's clean as a whistle buttons sewn on my project I don't have any of those threads hanging I've securely though I don't have to tie them off on the back side it's perfectly and it perfectly fits the button hole that we made okay so pretty pretty neat okay so that's your buttons selling foot so let's go ahead and I'm going to do a little bit with the satin foot next so your satin foot yes way move on here that leela bg had asked what do you do if your button is bigger than the slot and the button hole or foot you and need to manually create one with his execs stitch if it's really a lot longer than that just created with his execs stitch great thank you thanks for the question leela and yes one more from jane coups how is with measured on the button hole I'm not sure I understand the question, but the width of the stitch it just well, the pre selected I'll just pick stitch one o four for example, the one we just did and I'll pull up thie uh lengthen with selection, it gave me, like, kind of an optimum length and with for the stitch, the width is the distance from side to side of the whole buttonhole, so if I made that near, like everything would come in or go out depending on how I move this, I don't think it even gave me the option of going wider. It didn't I could go a little narrower, but it measures from side the outsides from outside to outside of the buttonhole think, but it gave me a pre selected kind of the most often used I don't have to think it actually gave me the best looking choice automatically know here you have your, um, general purpose foot for your construction sewing, and here you have your satin foot. So how are these really different and percentage stitching or any of that dense, decorative stitching your letter sewing? We've got built in lettering, I'll show you in just a moment the stitching we did, like on these little bags, anything that's real dense like this you would go to change to your satin foot and your satin foot is different on the back side if you turn these over and look you'll notice that the satin foot actually has a groove or a tunnel on the underside that lets the stitches pass underneath so if I was if you've been sewing any of these dense stitches and you've been using your regular press her foot and you've been having them like damn up or ball up in front of that or they're just not feeding along for the density of the look you want for your stitch it's because you've been using a foot that's meant to so really just basically you have stitches that where the foot needs to stay in contact with all the feed dogs for example your construction stitches but the decorative stitch would happen at the decorative stitch foot or satin foot you've got these two sides of the foot that stay in contact with the sides of the feed dogs but there's this tunnel on the underside that lets the density of the stitching pass underneath without getting stuck so you'll find that if you switch to this foot you'll so um more successfully those kind of stitches and it's wonderful because it's transparent and you can see your work is your sewing so we're going to switch to the satin foot and do a little bit of decorative work casey snapped that on and let's find a piece of fabric to stitch on so I've got this piece of gray here that I was going to use to do that it's, just a nice pretty charcoal grade at such a popular color right now, in home decor and fashion is charcoal gray. See it everywhere. It looks really pretty, with just about any color, you put it with just going toe getsem stabilizer. Whenever you do decorative machine stitching, you also want to add a stabilizer to the backside satin stitching, like, for example, a zigzag stitch when your satin stitching, and that would be an example of that might be something like this pillow here, where we did dense stitching, satin stitching just by nature. It was back and forth, back and forth, back and forth, and it contend to on your fabric. Want a kind of tunnel, a little bit tunnel in like that, and the way to avoid having that happened to you? Is it? If you use a stabilizer on the back side a tearaway stabilizer, they're available pretty much anywhere any fabric store carries then there's different brands of it out there and there's different weights of it too for your very light fabrics, you might want a lighter weight one for your heavier fabrics heavier one to support the weight of the fabric properly if he was a really heavy one with a very lightweight fabric when you go to tear it away, you can distort your stitches um and if you use a really light one with a heavier fabric, you can have it be wrote really doesn't support well enough so those should also kind of mary weight wise so but what will happen is you eliminate that puckering or that tunneling with your deck dense stitching so let's just try this with, say, a satin stitch and I'm going to put this her feet dogs were dropped so I'm going to push him back over to the right and turn my hand well toward me one revolution so they're back engaged and slide this tray back on cut my threads and we'll place our fabric underneath and I'll show you the difference too with what lengthen with khun do with your decorative stitches so um here is, of course, your zigzag stitch right here in your quick select buttons um you're this's your attention pre selected it at a seven member on the straight stitch it was at a ten so it knows I'm going to do a zig zag and it's probably decorative so it wants to relax it a little bit so you see how it just does my thinking for me but I can change it if I want to so that's tension over here then is my um excuse me then I want to go to my this is your backup button if you want to exit this screen this is your backup button and you press that one time and it takes you back to the previous screen and so then we could go to our stitch lengthened with button and now these function buttons have a new meeting that's our length and width again so we'll just stitch along and we want o make that narrower like for a satin stitch we would well you can press you have a needle up down button here at the fronts you could just touch that wants to raise the needle out of the fabric and then bring your with maybe to a little bit narrow setting for something like this may be about a three point five and but that's probably not short enough for a satin stitch so here I brought it a little narrower but I still needed to be I'm gonna raise my needle again by touching a button I want to bring that density down. A little shorter and let's give that a try we'll try about an o point eight and see how that looks really depends on what you want the final look to be it's a personal thing that still looks a little open for something like this so we'll raise the needle up again and will bring that stitch length down even smaller here's a no point for I don't have to worry about the stitches getting stuck under the foot because I've got the satin foot on it's got that groove and let's have a look at that see that's looking you see how the stitch length effects that just by pressing the plus and minus there I think I might even go down one more on the length there's a no point three to get a really, really, really sat me look and if you find that you brought your stitch length down as far as it will go it was cut that thread with the threat trimmer if you found that that is still not dense enough for your taste, you might want to change to a little bit thicker threat if you remember earlier I talked about ray on thread the ray on threats for example there was a forty waiting thirty wait perhaps maybe going to a thirty weight where the threat is a little thicker we'll give you the more filled in look that you're after for your satin stitching so what you would do here on the case like this is you would use a fabric marking pen or pencil and you would draw, draw your lines on your fabric, set it up for your sentence stitching and then just so along, following your lines as you go and to create an effect like this satin stitching is usually thought of with projects like application, an application here's an example of something we did that where we did this stitch much narrower than something like this. We did it about a good millimeter and a half or so narrower. Very, very dense. And this it was just a simple little application for an eyeglass case. Here's a case where the stitch was wider, like it was on this pillow to add this do peony silk to add the do penny so leaves to this christmas stocking and these satin stitches with a ray on thread. This is ray on this is ray on. This is more of a construction type of thread, but still beautiful and then here's. Here are more examples of satin stitch applicator where you can change the length and with as you prefer, okay, and you can also do applicator with other stitches as well, you've got a pin stitch in here, which is number twenty three. And you can bring that narrower and shorter to your taste and when you do that you can do an applicator like this where you're doing the little stitch around the edge rather than a satin stitch you're doing that little stitcher on the edge like so and it gives it a little more of a casual look um this was a raw edge on here when we applied that apple to the base fabric here's an example of where we have these tulips and these two lips were there not raw edge the leaves or the flower part are actually where the fabric edges were turned under and we used a blind stitch with a short with and a short length about it's a little hard to see I know because the thread matches the fab pretty well but you khun britain make your blind hem stitch narrower, narrow and short rather than the default setting used mostly for hemming, which I'll show you in a little bit to do applicator with your blind stitch seal often hear pin stitch apple k blind stitch applicator and to demonstrate application for you I'll go ahead and do that I've got a, um a heart applicator here on a piece of base fabric and I'm going to just reach over and grab a piece of stabilizer let's see here got one right here we'll put that on the underside of our underside of our heart and so I've adjusted the stitch it looks really good and we'll go ahead and place our heart underneath here and start sewing so when you're doing this on an actual shape, what you want to do is look for I like to say the zig and the zag of the stitch going to the left and the right help show you this, but you've got when you stitch on the heart, you should go into the heart with the left swing and then as it goes off the edge of the applicator, you want to go just off as it swings to the right, you want to go just off the edge of the applicator u s o u go zigzag like that zigs you wouldn't go zigzag way over here and have it really just straddling this in the middle. You can kind of see that sometimes you'll see the differences in the height of this in your stitch. So you want to have your stitching really cover well around the edge of the application and so let's, go ahead and do that, so I'm going to the left swing of the needle I want into the heart and then the right swing will be over just off the edge of the fabric, and now I could continue to seoul, but I've got something in the way of my foot here, okay? And don't force it, don't push it, just let it flow through it's a very short stitch length, so it'll seem like it takes longer to do than just straight sewing. We're on a bit of a straight away here, along the edge of this heart and will be coming up on an area very shortly that is curved, and we'll need to stop and pivot to negotiate the curves. How often you do that depends on how small or how curved your piece is so here's where you don't want to be just forcing, forcing this because you could actually just be twisting it too much for the size of the applicator. So I stopped with the needle down in the fabric, and I'm just going to lift the presser foot lifter and just pivot this a little bit and then continue to go. We'll do a little bit more, and as we come around and it's more curved, I'll stop again needle is done in the right hand side ah, lift and I'll pivot a little bit and you just continue to do that until you've gone all the way around your curve, like so on outside curves like I'm doing now, this would be considered an outside curve if I was sewing this way, that would be an inside curve. But when I'm on an outside curve like this you want to stop with your needle before you pivot you want to stop with your needle in the down position on the right hand side because if you were to stop with your needle on the left hand side like this and then lift and pivot you'd probably have a little open area on that outside edge and it would look like a gap and you wouldn't want that so you want to stop with it on the right hand side before you begin to pivot and then you eliminate that possibility and just continue around your heart like so and we just bring it down over here and so I think you can see what we're doing is we're getting this nice solid edger on the edge of our heart ends that's applicator but again you can use satin stitching for not just applicator but for embellishment as well when you finish around your heart for thread trimmer to really release that from your machine and then you would just go in the back side of your fabric and remove your tearaway stabilizer some of the folks were asking earlier today how do you how did you put the heart on the fabric and use a substance called the generic term for it isf usable web on and you can buy that at the fabric store the craft store and you would take your heart fabric and apply it to one side of the fuse. Herbal web following the manufacturer's instructions, and then you would cut out your shape. Take thie, backing off the fuse herbal web, and it has a surface. Then, that is. You can then take that heart and lay it on your base fabric and press that in place. There's different kinds that work a little bit differently, so you can choose the one that's right for you. But there are other fabric stores and craft stores.

Ratings and Reviews

user-a49565

I was surprised and impressed with the quality of the instruction I received from this course. I recommend it to anyone who owns this machine (which I am very happy with) and decided to buy it for future reference. I'm happy to know about Creative Live. I hope to find other great resources there.

a Creativelive Student

Awesome class! Although I've been using my 9960 for at least a year, I learned a ton! Becky is an excellent instructor. She explains things thoroughly, and it's so fun to see all the inspiring projects that can be created with the 9960! Thank you!

a Creativelive Student

The best. I accidentally found the "free" video and then bought the class. I started sewing as a child (I am now over 60) and am amazed at what I did not know. I love the 9960 machine. Becky has taken a sewing machine to a whole new level. Her knowledge, tips on uses of thread and attachments, showing items she made and what you can do was wonderful. Now I just need to get my "creativity" working. Thank you!